Pallet Exchangers for Retail Distribution

Retail distribution centres and grocery warehouses must handle high volumes of pallet transfers while maintaining hygiene and meeting pooling requirements. Pallet exchangers make it possible to repalletize quickly and safely without slowing the supply chain.

Why pallet exchange matters in retail

Hygiene and efficiency are vital for retailers. Pallet changers transfer products from supplier pallets onto clean, standardised pallets approved for in-store or DC handling. This reduces risks from wood debris, broken boards and contamination while ensuring compliance with pooling agreements such as CHEP or LPR.

Best-fit solutions

Stationary pallet exchangers work best at high-volume intake points, integrating with conveyors to handle supplier loads. Mobile units provide flexibility to handle exceptions such as damaged pallets or special returns, ensuring no disruption to outbound schedules.

Use cases

Retailers use pallet exchangers to swap produce, drinks and packaged goods onto hygienic pallets before storage. They also use them to rebuild pallets for store display, ensuring products are delivered on clean, sturdy bases.

Our Pallet Exchangers

Mobile Pallet Changers

Stationary Pallet Changers

Why Pallet Exchangers?

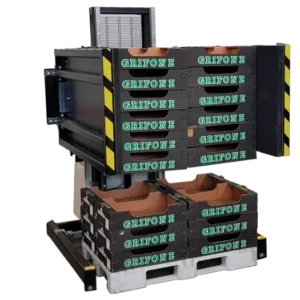

At Pallet Exchangers, we supply premium Toppy pallet changer machines across the UK, designed to replace wooden pallets with plastic (and vice versa) in seconds, without damaging your products.

Whether you need a mobile pallet changer for flexibility or a stationary unit for high-volume operations, our solutions are Italian-engineered, CE-certified, and ready for fast delivery.

Expert Support

We don’t just sell machines, we guide you through setup, training, and ongoing optimisation. Speak directly to our UK-based team anytime.

Fast UK Delivery & Demos

Need to test it on-site? We’ll ship a demo unit straight to your facility so you can see the results first-hand—no guesswork, no pressure.

Trusted & Certified Machines

All our pallet exchangers are CE-certified, safety-compliant, and manufactured in Italy to the highest industrial standards

Frequently Asked Questions

Why do retailers use pallet exchangers?

To transfer products onto clean, standardised pallets that are safe for DCs and stores.

Can they handle fresh produce and fragile goods?

Yes, non-tilting exchangers handle delicate loads like fruit, bakery items and eggs safely.

How do pallet changers support pooling schemes?

They ensure products are quickly moved onto CHEP, LPR or other retailer-approved pallets.

Can they be integrated into busy DC workflows?

Yes, stationary systems are installed at inbound conveyors, while mobile units cover exceptions and returns.

Do they help with store-ready pallets?

Yes, pallet exchangers ensure products are delivered on clean, sturdy pallets suitable for store display.

Book a Live Machine Demo

Trial the Falcon Wings machine, shipped to you anywhere in the UK.